RAM EDM, otherwise known as “Sinker EDM” or “Plunge EDM” has been around for over fifty years. As machining with Sinker EDM or Plunge EDM occurs by using electrical energy, the electrical conductivity plays a key role in how fast the Spark Gap can ionize allowing a spark to occur. Materials such as Carbides and Poly-crystalline Diamond (PCD’s) have lesser electrical conductive therefore take a longer time to machine.

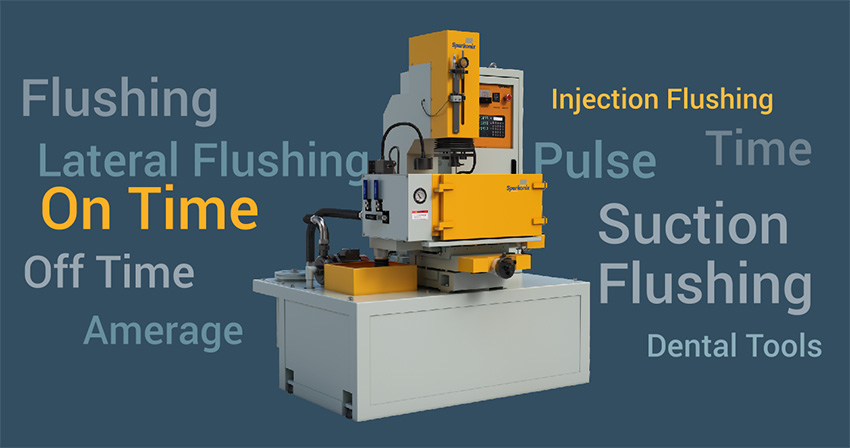

Here we take a look at the most common machining terminologies that are important in understanding the EDM Spark erosion process.

Pulse

An EDM Pulse is a controllable phenomenon, there are certain parameters that determine the intensity and spark size.

Time

Again time has been divided into two parts On-time and Off-Time

On-Time

On-time is the length of time Spark is in on stage and also defines the depth the spark can travel. It directly impacts the final part size and surface finish.

Off-Time

This is basically the gap between the Sparks. This time has defined as the basis of cooling period requirement and chip removal time.

Amperage

The higher Amperage means higher spark. Amperage is basically the electrical power of the spark. similarly, Amperage also has a deep impact on part size and its finish

Flushing

In the EDM process, Flushing is a very important part. It removes contaminated fluid and eroded particles, and replaces them with clean, temperature-controlled fluid.

There three basic types of Flushing

Injection Flushing

Injection Flushing, here cooled dielectric fluid is injected through the electrode during the spark gap. This is the most efficient type of flushing for many jobs as it basically pressurizes the spark gap around the electrode to keep a continuous flow of fluid going from the bottom of the cavity up to the sides and out the top.

Suction Flushing

Here a vacuum line is attached to the bottom of the cavity and fluid and debris flow to the suction point. Ideal for parts which produce Small debris type substances this flushing can be used in combination injection flushing

Lateral Flushing

Here external nozzles are used to create a flow of dielectric fluid across Job. However, this is not an effective way of flushing

Many modern EDM machines have several technologies that assist with or compensate for poor flushing situations.