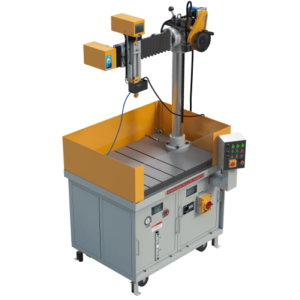

The ideal choice for Tool Room operations!

Archimedes said “Give me a place to stand and I will move the earth” to illustrate the concept of lever.

American Axle and Manufacturing have been moving the world from the 30 facilities in 13 countries while illustrating the power of innovation.

AAM is the leading, global tier-one automotive supplier of driveline and drivetrain systems and related components for light trucks, SUVs, passenger cars, crossover vehicles and commercial vehicles with a regionally cost competitive and operationally flexible global manufacturing, engineering and sourcing footprint.

Meet Mr. Prashant Patil, the man who played a key role in shifting the entire Land Rover plant from UK to India. In an illustrious career spanning over 26 years, Mr. Prashant Patil has worked with the best and the biggest players in projects handling. Co-incidentally, his love for machines began with EDMs during the experience at Electronica Machine Tools, early in his career. He has worked with leading engineering companies such as Poonawalla Group, Bharat Forge, Hofler-India, Mahindra and Mahindra etc. Excerpts of the interview with him.

Most importantly, Sparkonix is a product of India. The founders have put their ideas, experience and expertise of over four decades to bring the world-class, innovative features at such a low price. The resultant value for money is immense.

What is the next thing in machine tool industry?

Innovate!

Innovation in safety and economics in terms of machine capacity and operational costs will be the key. In the immediate future, I see a strong trend for total automation including implementation of Manufacturing Execution Systems (MES). However, in case of tool room machines the performance level will matter more than the degree of automation.

How do you look at low cost imported machines from countries such as China, Taiwan etc.?

My personal point of view is – do not fall for just the looks and features. In machine tools, the manufacturer and buyer have to be made for each other. The dependency on critical spares in case of imported machines turns to be costly at times. The fact that these spares are not indigenous, further aggravates the risks of buying these machines.

How was your experience of using Sparkonix’s EDMs?

Sparkonix is a perfect machine for tool room activities. I will rate it very high, say, 9 out of 10!

Most importantly, this machine is a product of India. The founders have put their ideas, experience and expertise of over four decades to bring world-class, innovative features at such a low price. Thus, the resultant value for money is immense.

What is your message to the peers?

It’s relatively difficult to get people with core expertise in machine tools.

As tool room managers we need to train our folks properly, especially on fundamental concepts. Often, we have the best of the machines but we need to invest a good amount of time to match the skill set of the people to use the advanced features in our machines. Mistakes are costly and only way to avoid them is by training the workforce.